Capabilities

Precision Machining for High-Stakes Manufacturing

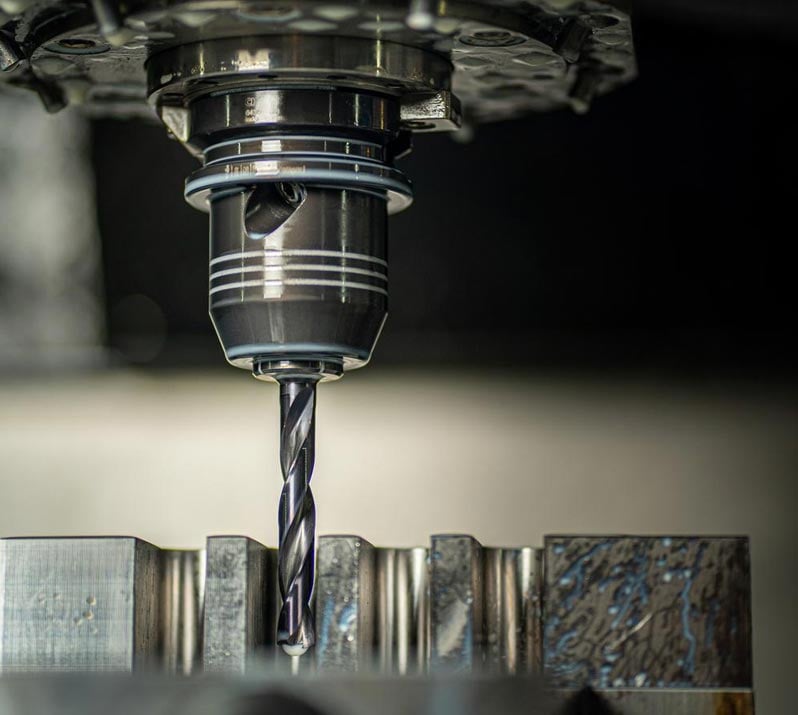

At Excelus, we specialize in CNC machining complex components from metals and engineered polymers—whether you need a one-off or 10,000+ parts. We offer milling, turning, and grinding with some of the fastest lead times in the region.

But we’re more than a machine shop—we’re your partner in precision manufacturing. Our engineers work with you to solve tough challenges, improve performance, and deliver smarter, more cost-effective solutions.

5-Axis Milling Services

We specialize in machining complex geometries across a range of materials, which is why we’ve invested in advanced 5-axis milling. By accessing five faces in a single setup, we improve precision, reduce setups, and lower costs.

Unlike traditional shops, we don’t just machine parts — we collaborate with our customers to optimize designs for manufacturability and performance. Our goal is to act as an extension of your engineering and procurement team, delivering smarter, faster solutions.

-

What is 5-Axis Milling?

Until recently, milling machines had just three axes, X, Y, and Z. For someone facing the machine, X is where the work holding table moves left-right, Y is the table moving backward and forwards, and Z is it moving up and down. From many prismatic parts, (those with straight, square sides and surfaces,) this is enough “degrees of freedom” to machine any required features. However, parts that need non-orthogonal (not 90°) surfaces require additional setups.

5 axis milling addresses this problem. This adds two rotational axes to the three linear axes. Machine designs vary, but typically a 5-axis milling machine adds A and B axes. These provide rotation around the X and Y axes. Other machines add B and C rotational axes, (rotation around the Y and Z axes), and there are probably some somewhere with A and C axes.

-

What is the Advantage of 5-Axis Milling?

The big advantage of 5-axis milling machines is that the cutting tool can reach five faces of a prismatic part. (The part is mounted on the sixth face.) Many 5-axis machines provide what’s called, “5-axis positional machining.” This means the axis rotates to a fixed position, and then the cutter starts removing metal. This is useful for applying chamfers or cutting grooves and dovetails, but it’s not full 5-axis machining.

Full 5-axis machining is where the rotational axis turns as the part is being machined. With this, the cutter can produce contoured surfaces, like those on a turbocharger impeller or fan blade.

-

Other benefits of 5-Axis Milling

All this additional capability, over 3 axis machines, doesn’t come cheap. In addition, programming 5-axis milling machines is complicated. However, for some parts, there are substantial benefits. These include:

- Fewer setups to produce complex shapes – because the cutting tool can reach more surfaces

- Less expense on fixtures

- Superior geometric precision between features otherwise produced in separate setups

- Ability to machine contours

- Improved surface finish – because the machine allows for shorter cutting tools that suffer less vibration

-

Maximum Part Size for 5-Axis Milling

- 5-Axis Milling (1 Mill)

- Max Travel: 21” x 16” x 19”

- A,C Axis Travel: +30°/-110°, 360°

- Max Weight on Table: 330 lbs

3-Axis Milling Services

We use 3-axis milling to produce high-precision prismatic parts like brackets, housings, and mounting plates. It’s ideal for flat surfaces and clean edges, offering reliable accuracy across prototypes and production runs.

With advanced equipment and expert programming, we deliver tight tolerances and consistent results. Whether you’re working from CAD or a concept sketch, our team helps optimize designs for performance, manufacturability, and cost.

-

What is 3-Axis Milling?

Milling is a material removal process that uses a spinning, multi-toothed cutter. The rotation lets each tooth cut away a small slice of material. We do most of our milling on vertical machines. These hold the cutter on a vertical axis and move the workpiece underneath in X and Y axes. (If you stand facing the milling machine, or mill, X is left-right and Y is front-back.)

-

What is the Advantage of 3-Axis Milling?

These two axes suffice for milling flat surfaces and sides. They are not enough though to produce features of varying depth. Picture milling pockets into a solid block of metal for an example. To produce pockets of different depths in a single set up the machine needs a third, vertical axis. This is achieved by raising and lowering the spindle in what’s called the Z-axis.

Milling machines are also produced with the cutter axis horizontal. Horizontal machines have the same three axes of motion and tend to be very rigid but are, arguably, less versatile than vertical machines.

It’s our experience that our 3-axis milling services satisfy the overwhelming majority of prismatic part machining requirements.

-

Other benefits of 3-Axis Milling

3-axis milling is cost-effective, widely available, and ideal for a broad range of part types. It’s great for fast turnarounds, especially on prismatic parts like brackets, housings, and plates. With fewer moving parts than more complex machines, 3-axis mills are easier to program and maintain—making them a reliable choice for both prototyping and production. When used with skilled programming, they can produce highly accurate parts with excellent surface finish.

-

Maximum Part Size for 3-Axis Milling

- 3-Axis Milling (9 Vertical CNCs, 2 ProtoTRAKs)

- CNC Max Travel: 50” x 18” x 18”

- ProtoTRAK Max Travel: 38” x 20” x 17”

CNC Turning Services

We specialize in CNC turning of complex geometries with tight tolerances in demanding materials. Whether you need one part or 10,000, we offer fast lead times and flexible volume capabilities.

Our in-house engineering team can optimize designs for better machinability and lower cost. We work from drawings, sketches, photos, or sample parts—and we’ll suggest improvements when we see them. Our goal is to be a true partner in your CNC turning projects.

-

What is CNC Turning?

Turning is the process of creating cylindrical forms. The workpiece is held in a chuck, or sometimes a collet, that rotates. A cutting tool is brought to the side of the workpiece and moves parallel to the workpiece axis to reduce or “turn down” the diameter. With careful setup, turning can also produce tapers or cones and cylindrical bores.

For generations turning was performed on manual machines. Then, in the 1960s and 70s, Computer Numerical Control, or CNC came along. With this, the motion of the lathe spindle and tool holder X and Z axes are managed by a computer program. Speed and movement are controlled to extreme precision, and most importantly, the movements are totally repeatable.

-

What is the Advantage of CNC Turning?

The beauty of CNC turning is that it’s capable of producing complex parts in the least possible time. This makes it as powerful for one-offs and prototype parts as for long runs. When used for quantity production, advanced control technology means the finish and geometry of the last part will be the same as the first part.

A limitation of turning is the surface finish that’s achievable. As a single-point cutting process, turning produces a finely grooved surface. Selecting a large radius cutting tool and reducing the feed rate minimizes this texture but it’s hard to achieve an Ra better than 25 µinch/0.63 µm. That’s why, for precise surface finishes, turning is usually followed by grinding.

-

Other benefits of CNC Turning?

Shafts, valve spools, collars, hubs, pulleys, and couplings are just a few examples of parts produced by turning.

Some of these will subsequently need grinding, especially if they incorporate bearing journals or surfaces with precision fits like valve spools.

We do offer extensive grinding services.

-

Maximum Part Size for CNC Turning

- Turning (3 Lathes)

- Max Turning Diameter: 14”

- Distance Between Centers: 23”

- Swing Over Diameter: 20”

- Max bar capacity: 2”

CNC Milling Services

CNC milling is ideal for producing flat, straight surfaces with speed, accuracy, and repeatability. At Excelus, we handle everything from prototypes to high-volume production. Whether your parts need milling alone or a combination of processes, we’re ready to help.

Our team works with you to optimize designs for cost and manufacturability, acting as an extension of your engineering group. From quick-turn replacements to long-term production, we’ve got you covered.

-

What is CNC Milling?

Milling is the process of removing material with a rotating, multi-toothed cutter. CNC, the acronym for Computer Numerical Control, refers to having the machine movements controlled by a computer. A part program, developed from the CAD file, dictates the sequence of moves that remove material to create the part. It can do this faster and more repeatably than is possible with a manually-controlled machine.

Milling machines take one of two forms, although a third variant is on the rise. The two forms of milling machines are vertical and horizontal machines. This refers to the axis of rotation of the cutting tool. Vertical machines hold the tool on a vertical axis. They are more widely used than horizontal machines because they tend to be more versatile.

-

Staying Current with our Technology and Equipment?

5 axis CNC machines are the new, third type of milling machine. A vertical mill has three axes of movement: the table that holds the workpiece can move left-right (the X-axis,) and forwards and back (the Y-axis.) In addition, the spindle can move up and down to provide a third, Z, axis. With this arrangement, a vertical machine can cut flat surfaces on any exposed surface of the workpiece.

A 5-axis CNC machine adds two additional axes of movement. This lets its angle and tilt adjust to the cutter axis with respect to the workpiece. This has two advantages over a 3-axis machine: it enables machining of contours, and it reduces the need to take the workpiece off the table and remount it in a different position to machine additional features. That saves time and helps maintain a tight geometric relationship between the machined surfaces.

-

Our Maximum Capabilities for CNC Milling

3-Axis Milling (9 Vertical CNCs, 2 ProtoTRAKs)

- CNC Max Travel: 50” x 18” x 18”

- ProtoTRAK Max Travel: 38” x 20” x 17”

5-Axis Milling (1 Mill)

- Max Travel: 21” x 16” x 19”

- A,C Axis Travel: +30°/-110°, 360°

- Max Weight on Table: 330 lbs