Strengthening Supply Chain Security in Precision Manufacturing

In today’s global market, supply chain resilience isn’t just a competitive edge, it’s a requirement. At Excelus Manufacturing Solutions, our...

1 min read

Heather Mayo

:

Oct 22, 2025 1:29:17 PM

In the fast-paced semiconductor industry, precision and throughput must coexist. Over the past three years, Excelus has partnered with one of our largest customers to triple production output for a critical, tight-tolerance component, all while maintaining the exacting quality standards this industry demands. And we’re not stopping there: plans are already underway to double production again in the coming 12 months.

Semiconductor components require incredibly tight tolerances, consistent quality, and efficient delivery. Our customer needed to dramatically increase output without sacrificing precision, something that traditional approaches to scaling production couldn’t achieve.

Lean Study of Part Families

We began by performing a comprehensive Lean Study to analyze part families and identify the most effective production flow. By understanding similarities and variances, we created a roadmap for efficiency gains across the entire process.

Pilot Flow Line Testing

To validate our approach, we tested the Lean Study thesis with a single dedicated flow line. This proof of concept demonstrated measurable gains in throughput, accuracy, and operator efficiency.

Strategic Capital Investment

Over two years, Excelus invested more than $1 million in capital expenditures, repeating these optimized flow lines and redesigning the shop floor layout. The result was maximum operator efficiency and smooth, continuous part flow.

Organizational Training

We reinforced these changes with dedicated training throughout the organization, ensuring every employee was fluent in the new methodology. This commitment eliminated downtime, reduced scrap, and drove cultural adoption of Lean principles.

Building on this momentum, Excelus is now investing in advanced equipment, software, tooling, machine monitoring, and engineering talent to once again double production capacity in the next 12 months.

3x increase in production output in three years

Scrap and downtime reductions through training and Lean adoption

Optimized operator efficiency via redesigned shop floor and flow lines

Clear roadmap to double production again in the near term

Through data-driven Lean studies, strategic investments, and organizational training, Excelus continues to redefine what’s possible in high-precision manufacturing for the semiconductor industry.

In today’s global market, supply chain resilience isn’t just a competitive edge, it’s a requirement. At Excelus Manufacturing Solutions, our...

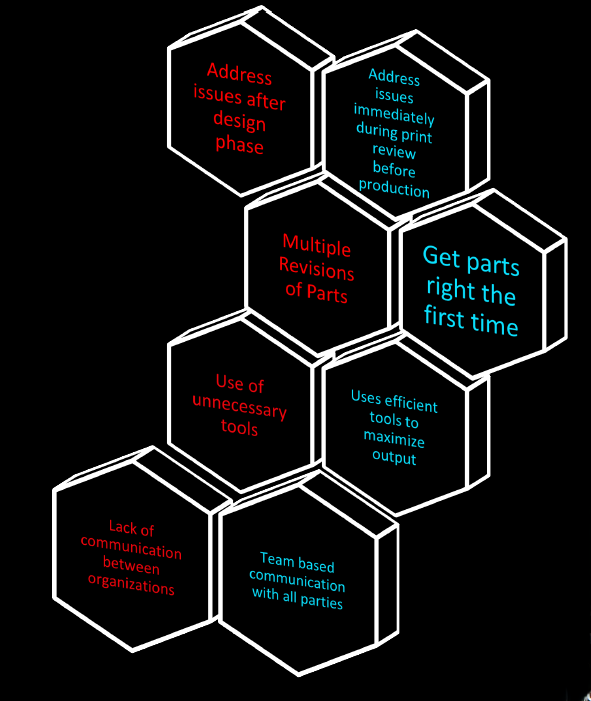

At Excelus, we believe the best way to build exceptional parts is to start with exceptional design.

At Excelus Manufacturing Solutions, we’ve learned that the most efficient way to solve a manufacturing problem is to prevent it from happening in the...